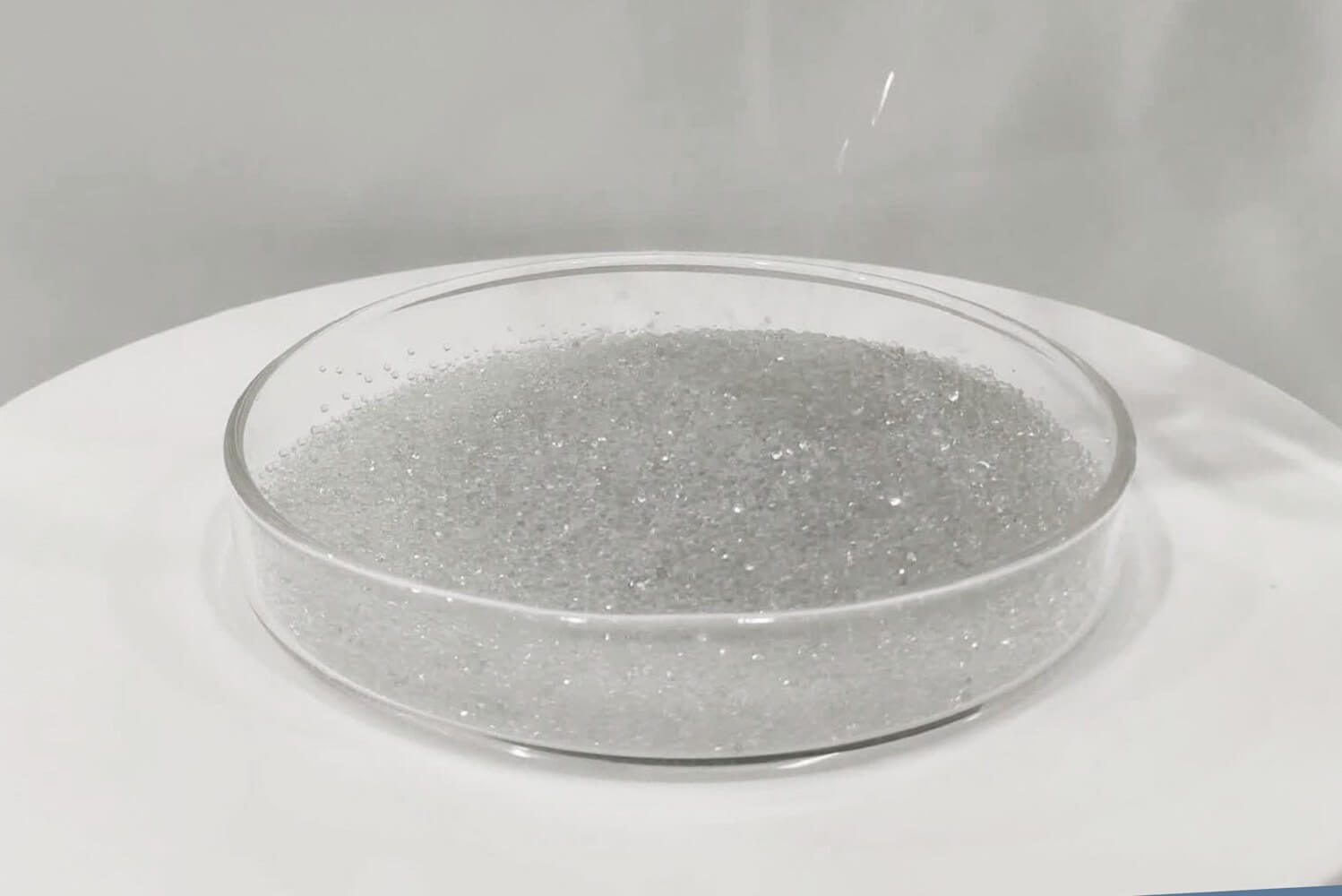

Glass Beads for Sandblasting are typically consumed at a slow rate in bead blasting equipment. Additionally, they also survive multiple impacts and thus can be recycled several times. Glass beads, made of recycled glass. Therefore, they are chemically inert. Thus the leave no ferrous or other undesirable residues on the prepared surface. When used properly, glass beads leave a controlled and clean finish on the prepared surface.

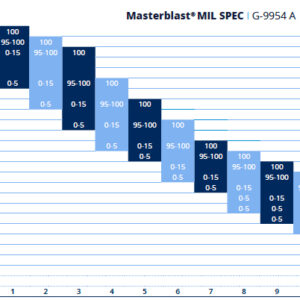

Glass Beads for Sandblasting Sizes

- Coarse Beads

First, larger beads remove larger and/or tougher materials from the surface. Next, larger beads produce a more intense peening effect and peen deeper into the material surface. Finally, coarse glass beads are consumed faster at the same pressure as fine glass beads. - Fine Beads

In contrast to course beads, finer beads remove smaller materials from the surface. Therefore, fine beads tend to clean faster, produce a less intense peening effect, and peen less deep into the material surface. Next, finer glass beads are more capable of reaching into smaller spaces on the material being prepared. As a result, finer glass beads can produce a matte finish when properly used. Finally, fine beads also consumed slower at the same pressure as coarse beads. - All Bead Sizes

For all sizes of glass beads: bead size, angle of the blast nozzle, the shape of the workpiece, distance from the workpiece, air pressure all dramatically affect the ultimate surface preparation and media consumption. Additionally, direct vs. siphon-feed bead blasting equipment also affects how glass beads usage and consumption.

Glass Beads for Sandblasting Uses

- Cleaning

When used properly, glass beads can clean a surface without significantly changing tolerances or introducing pollutants. - Finishing

When used properly, glass bead media can create a wide range of easily reproduced and unique surface finishes. - Peening

Using glass beads can help improve the tensile strength in metal parts and reduce stress corrosion cracking. - Deburring

Glass beads are an excellent abrasive media for removing burrs from the material without significantly removing the actual prepared material.

Kai (verified owner) –

Very well worth the money.