Is glass beads abrasives media can use for engine blasting job?

Is glass beads abrasives media can use for engine blasting job?

Professional Supplier For Glass Beads

We have different types of glass beads and relative products available in competitive price among markets.

Expert Manufacturer of Glass Beads for Road Marking

HAIXU is your best solution for road marking and industrial purposes with our comprehensive and high-quality road marking products.

HAIXU Offers a Wide Range of Blasting & Abrasive Glass Beads

Suitable for various applications in the industrial field, such as sandblasting, grinding, drilling, etc.

Haixu is mainly dedicated to supplying high-quality glass beads for road reflective marking, weighted blanket, sandblasting, paint, and other industrial purposes, micro glass beads play a very important role in the industry and daily life, with rich experience and excellent technician, Haixu has glass beads for various applications and will supply the best industrial material/media for you.

Road reflective glass beads are a kind of fine glass sphere formed by melting glass sand (waste glass) at high temperatures. It is spherical under the microscope, colorless, transparent, and the refractive index is 1.5-1.64.

Road marking glass beads play a very important role in road safety, they are mixed or dropped on paint to reflect light back to the driver especially in the dark or poor weather conditions. When the car light shines on the marking, the glass beads will reflective, and make the marking very clear.

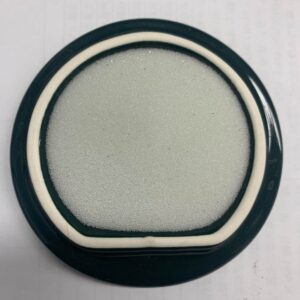

Blasting glass beads will be shot on the surface of objects under the pressure of compressed gas with high pressure and high speed, the surface of objects will be burnished or the interior stress will be a relief.

Shot blasting glass beads as an abrasive material has the following advantages over any other abrasive material: in addition to metal abrasive materials, longer than any other medium, made of non-alkaline soda-lime glass material, with Good chemical stability, will not pollute the processed metal, can accelerate cleaning, while maintaining the processing accuracy of the original object.

Glass beads are good blasting and abrasive media which can be used in an industrial area, For cleaning, finishing, peening and deburring applications. This media generally gives a brighter matte finish.

The raw material of the glass beads is glass sand, which is fused into a spherical shape by high-temperature suspension and then annealed to eliminate internal stress and prevent breakage. This transparent, clear spherical structure product does not have particles embedded in the workpiece during use, contaminating the workpiece or causing other damage. Using different sizes of abrasives and different operating parameters, the glass beads will have a special decorative effect by selective localized controlled blasting on the surface of the workpiece.

Weighted blanket glass Beads are made of first-grade broken glass, flat glass, and other raw materials by high temperature melting bead processing.

Low thermal conductivity, high strength, good chemical stability, and the texture of glass beads themselves, glass beads instead of plastic raw materials are widely used in the filling, such as gravity blanket filling, compression filling, medical filling, weighted blanket filling, toy filling and so on.

Is glass beads abrasives media can use for engine blasting job?

what’s the popular size of glass beads for metal sandblasting?

Is any kind of sandblasting glass beads have 9.0 moh’s hardness?